“Advancing Science Through Computers”

The Centre for Computational Science

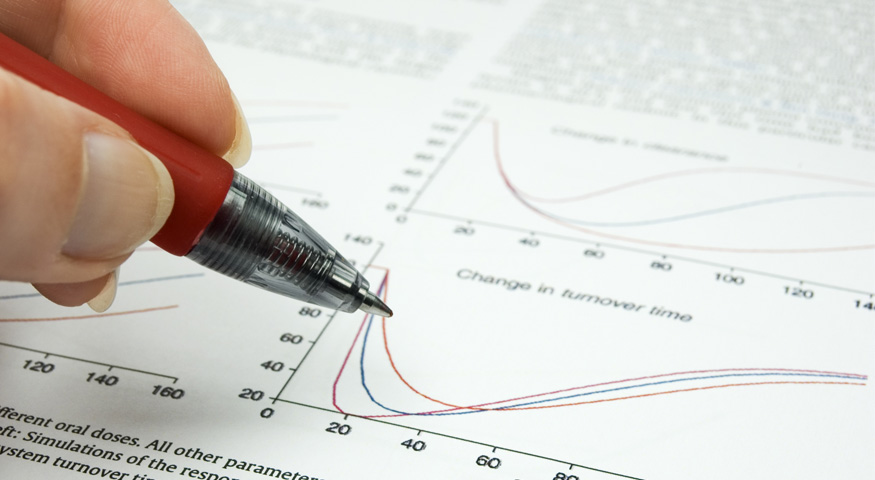

The CCS is concerned with many aspects of theoretical and computational science, from chemistry and physics to materials, life and biomedical sciences as well as informatics. We explore these domains through high performance, data intensive, supercomputing and distributed (grid/cloud) computing.

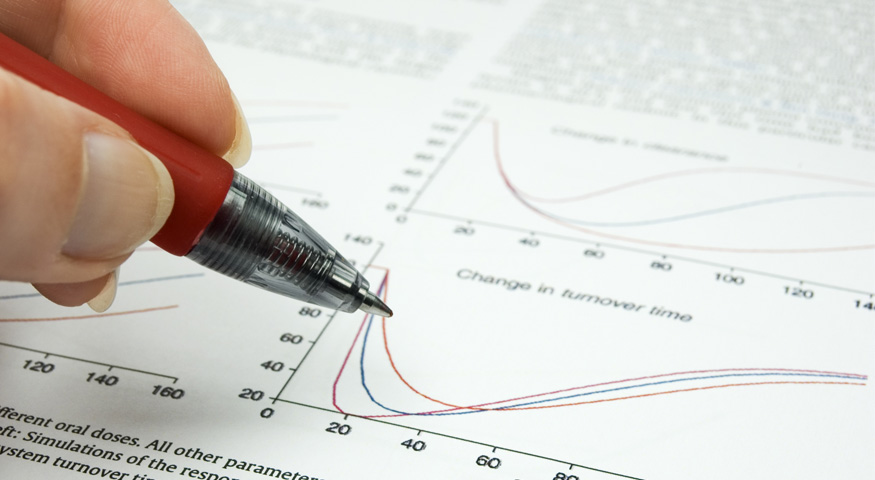

Our different computational techniques span time and length-scales from the macro- through the meso- to the nanoscale. We are committed to studying new approaches and techniques that bridge these scales.

We hold numerous grants from a diverse set of funding agencies.

We are committed to advancing science through computers.

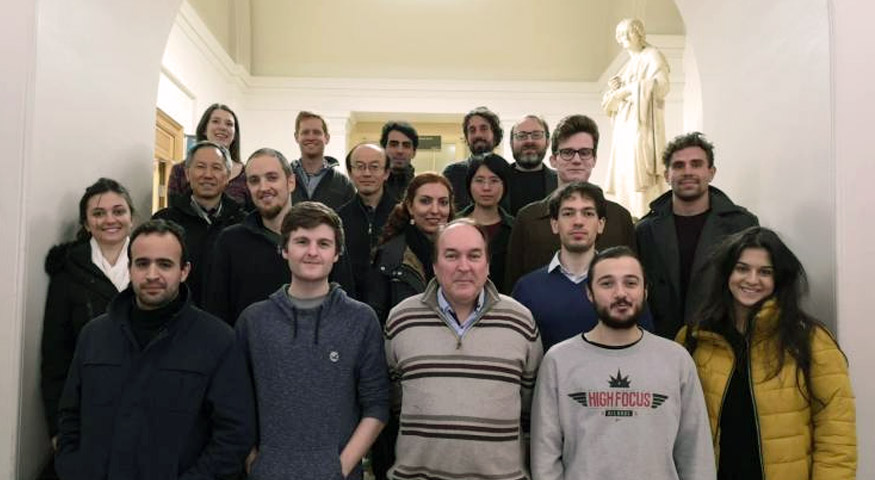

Learn more about the Computational Science team.

Find our repository of research publications.

View positions avaliable with the centre.

Keep up to date with our work.

Close

Close